Defining Work Order Units of Measure in Sage X3

Defining Work Order Units of Measure in Sage X3

Defined units of measure allow different parts of a business to transact in varying ways while ensuring that quantities and costing are accurate. In this blog post, we’ll take a look at what you need to do when you have operations with different units of measure.

Note: Content for this blog post was originally posted on Sage City by Joel Singam, September 28, 2021.

Work order operations can be tracked based on the default unit of the stock, the unit of the produced good, or the unit set on the operations.

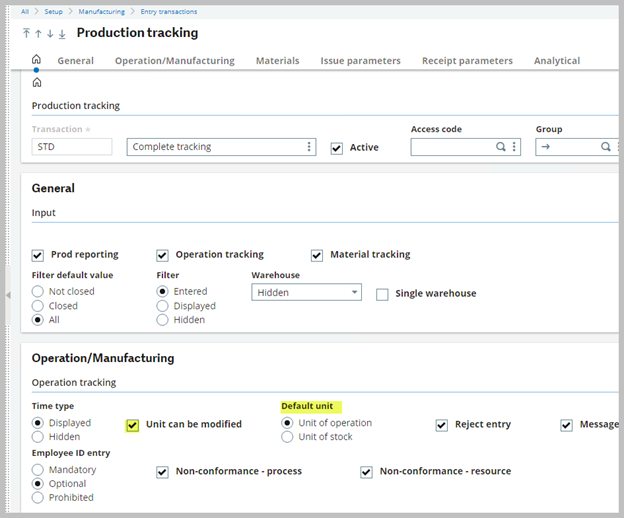

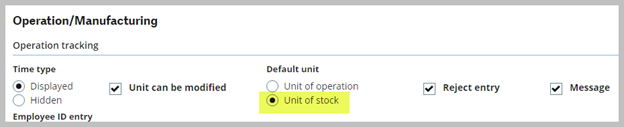

Go to Setup > Manufacturing > Entry transactions > Production tracking and click on the Operation/Manufacturing tab. There you will see the Default unit selections. To enable the default unit selections, check the Unit can be modified check box. You will see the options Unit of operation and Unit of stock available for selection. When the default operation is set to Unit of operation, you can define an operation unit that is different to the product being produced by the routing.

For example, a product managed by unit is subject to three different operations, none of which produce intermediate stock:

- Operation 1: Mixing time – is expressed for a lot in Kg.

- Operation 2: Extrusion time – is a rate in meters per hour.

- Operation 3: Cutting time – is expressed in hours per unit.

By using different units for each operation, it eliminates the need to create semi-finished products for each production phase.

The operation unit is associated with a conversion coefficient for the stock unit of the product being produced by the routing and the operation unit.

To illustrate this, we’re going to select the STD production tracking entry transaction and a production BOM with two different operations with different units.

Unit of measure:

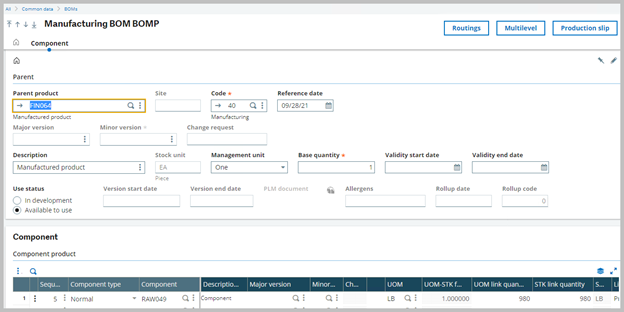

- Finished product = EA (each)

- Pack unit = PAL (pallet)

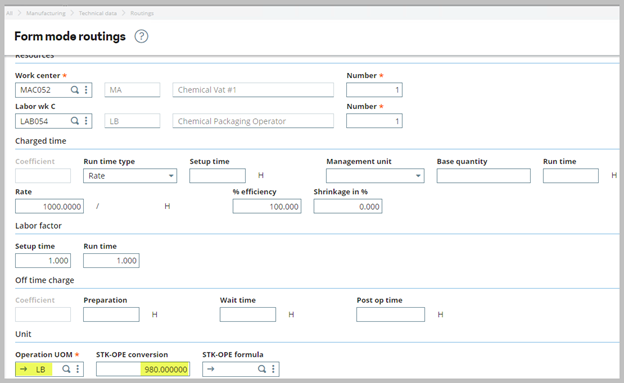

- Operation 10 unit = PAL (STK-OPE conversion is 980.00)

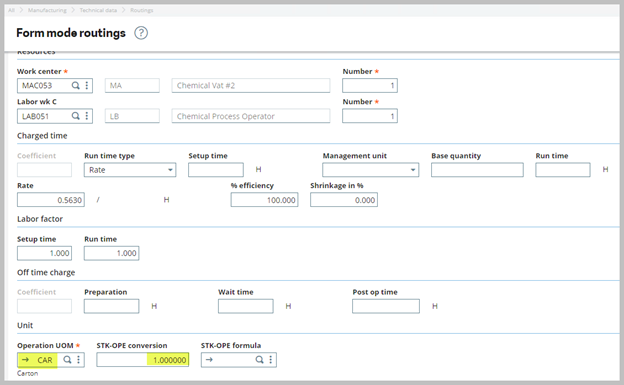

- Operation 20 unit = CAR (carton) STK-OPE conversion = 1

Production tracking entry transaction, default unit = Unit of operation

Production BOM setup with one component line.

For each routing operation use a different unit of measure and a coefficient:

Operation 10

Operation 20

Generate a Work order for a released quantity of 20 PAL.

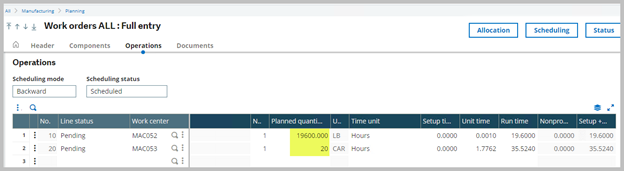

On the work order operations tab, take a note of the planned quantity which is expressed in the operations unit.

- Operation 10 = 19,600.00 LB (980.00 x 20)

- Operation 20 = 20.00 CAR (1 x 20)

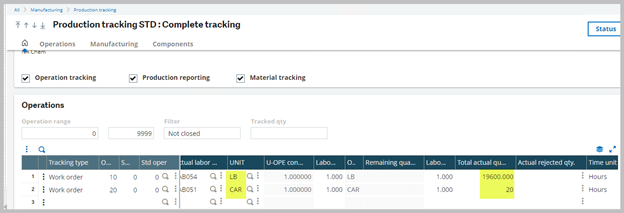

Generate a production tracking using the STD entry transaction.

Total actual quantity is showing the quantity tracked based on the above parameter and its coefficient.

Next, change the production tracking entry transaction default unit parameter to Unit of stock.

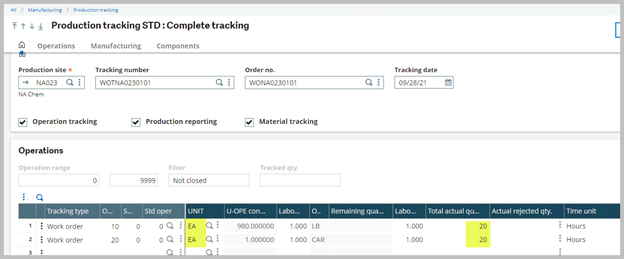

Generate a new Work order and track the work order.

Notice, total actual quantity is 20 EA for both operations, which is the stock unit of the finished product.

I hope this setting is useful when you have operations with different unit of measure.

For more information on how to handle operations with different units of measure, or for any other questions about Sage X3, please contact us.