SAGE X3 ERP FOR FOOD & BEVERAGE MANUFACTURING

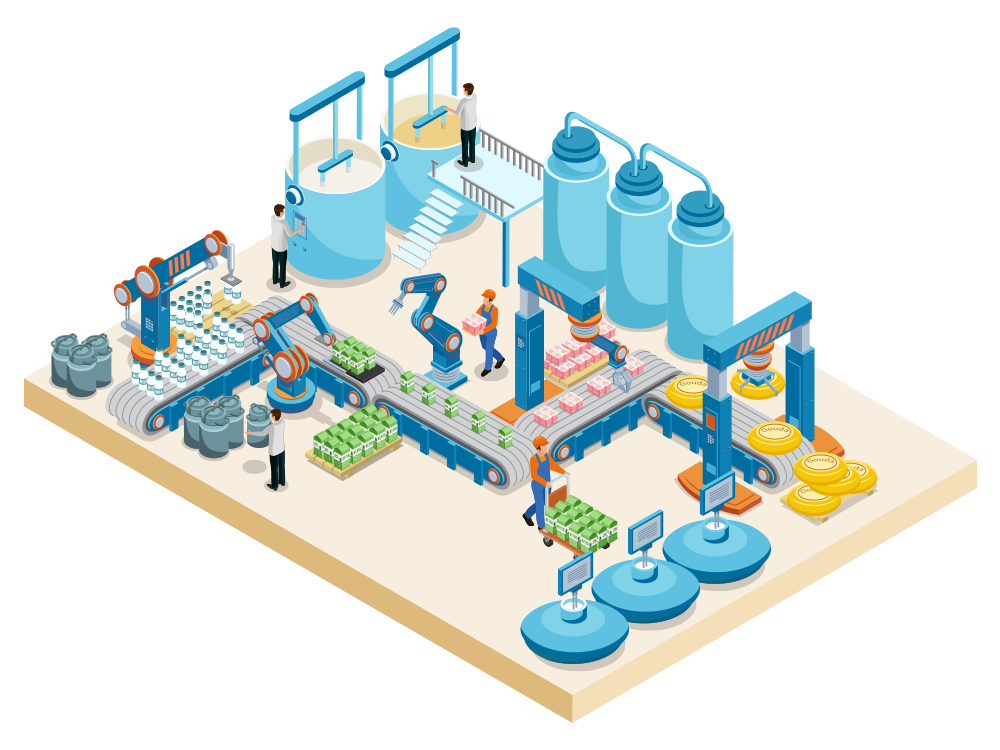

Sage X3 ERP, ERP for food manufacturing, takes on the management challenges that come with being a food and beverage manufacturer, processor or distributor. Fill out customer orders, manage recipes, control inventory, plan and manage production, all while staying compliant with ever-changing government regulations.

What Challenges Do Food Manufacturers Face?

As a food and beverage processor or distributor, your company must effectively tackle the challenge of managing industry-specific requirements and legal mandates imposed on your business. Not only must you efficiently fill customer orders, manage recipes, control inventory and plan production in an increasingly competitive environment, but you must also deal with the multitude of complexities resulting from increasing government regulations.

Additionally, economic conditions have fueled rising costs that are difficult to pass on to consumers. To be successful, you must be exceptionally focused on operational excellence. You can’t afford any production errors, waste, spoilage, recalls, safety issues or other events that will adversely affect your business.

Addressing the Most Pressing Challenges

A food ERP software solution targets these challenges directly through industry-specific capabilities such as recipe management, quality control, regulatory compliance and lot tracking.

Here’s how it works:

Challenge: Compliance requirements and legal mandates.

Solution: An ERP solution designed for the food and beverage manufacturing industry, with governance features built in, makes compliance monitoring and reporting a natural part of doing business.

Challenge: A need for efficiency in fulfilling orders.

Solution: Automation features within a food ERP platform allow for quicker processing and order management, with less time required for manual data entry and reduced risk of human error.

Challenge: Recipe management demands.

Solution: A cloud-based ERP allows employees to access consistent recipe and formulation information from any location, ensuring standardization and quality while assisting with record-keeping.

Challenge: Inventory control needs

Solution: Modern ERP solutions allow visibility into inventory across warehouses, distribution centers and partner organizations. This level of oversight helps prevent excess stock and stock-outs.

Challenge: Intense competition.

Solution: Businesses with advanced ERP systems gain improved decision-making and planning capabilities, helping them stay one step ahead of less technologically advanced food production competitors.

Challenge: Rising costs due to economic conditions.

Solution: The streamlined business operations enabled by a manufacturing ERP system allow a food manufacturer to do more with less and stay effective during challenging economic conditions.

Sage X3, the leading ERP software tool for the food and beverage manufacturing sector, allows you to add these capabilities and more. By transforming your business for speed and efficiency, gaining greater visibility into all your data and creating a single source of truth for the whole organization, Sage X3 delivers competitive advantage within your role as a food manufacturer.

How ERP Powers the Future of Your Food Manufacturing Company

Food companies need more than just a food manufacturing ERP software provider — they need an expert partner. With Net at Work, forward-thinking companies are gaining that and more.

Why? Because we help clients leverage Sage X3, ERP for food manufacturing, to its full potential. In fact, with us in your corner, you can:

- Reduce excess inventory by 10-15% and improve inventory turns

- Reduce working capital and free 15-20% of cash tied into inventory

- Reduce time spent on forecasting by as much as 50%

- Improve fill rates by 2-10% and eliminate stockouts

Net at Work’s Value as a Partner

Our team delivers technology expertise to ensure the Sage X3 platform is deeply embedded into your operations. The software can only reach its maximum effectiveness when the platform is integrated with all other relevant systems and employees at all levels of the organization are comfortable using the new technology.

We bring our core values to every engagement. That means:

- The knowledge to solve your challenges.

- Processes carried out with honesty, integrity and commitment.

- Collaboration based on trust and unity.

- A driven attitude designed to exceed, not just meet, goals.

- Coaching to ensure everyone understands the new solution.

When you work with Net at Work on your food ERP implementation, you don’t just gain a new piece of technology. You can count on the support and knowledge of our people to ensure your business is optimally efficient now and prepared for the future, whatever that means for your sector.