Heavy Equipment Manufacturer Finds Concrete Solutions with Net at Work

The award-winning curb extrusion equipment manufacturer, Power Curbers Companies, has been helping contractors construct barrier walls, sidewalks, curbs and other projects with excellence for 70 years. The Power Curbers Companies’ complex, configure-to-order machine manufacturing and global onsite assembly operations require concrete business management solutions to sustain its ongoing focus on lean manufacturing, waste reduction, and an unmatched customer experience.

For years, Power Curbers Companies had relied on Sage 500 as its accounting and Enterprise Resource Planning (ERP) system. But mounting struggles to integrate its CRM application, support its field service teams properly and maintain an application written in Visual Basic left the heavy equipment manufacturer with too many manual, disconnected, and time-consuming processes.

A COMMITMENT TO SUCCESS

Power Curbers first engaged with Net at Work at a conference, ultimately partnering with the top technology advisor to overcome the manufacturer’s technology struggles. “When we decided to partner with Net at Work, we used the move as an opportunity to upgrade our ERP and CRM to run our operations the way we needed,” explains Mark Hofer, CFO of Power Curbers.

The manufacturer underwent a software evaluation process with Net at Work, considering Epicor and Acumatica before deciding on Sage X3, as hosted by Cloud at Work. “We found that Sage X3 had the proven combination of core manufacturing and configuration to structure the system well for our business,” says Hofer. “And with Net at Work, we feel we have the in-depth solution expertise and industry knowledge to assist us with cloud hosting, programming, accounting, manufacturing, and whatever else crops up over time.”

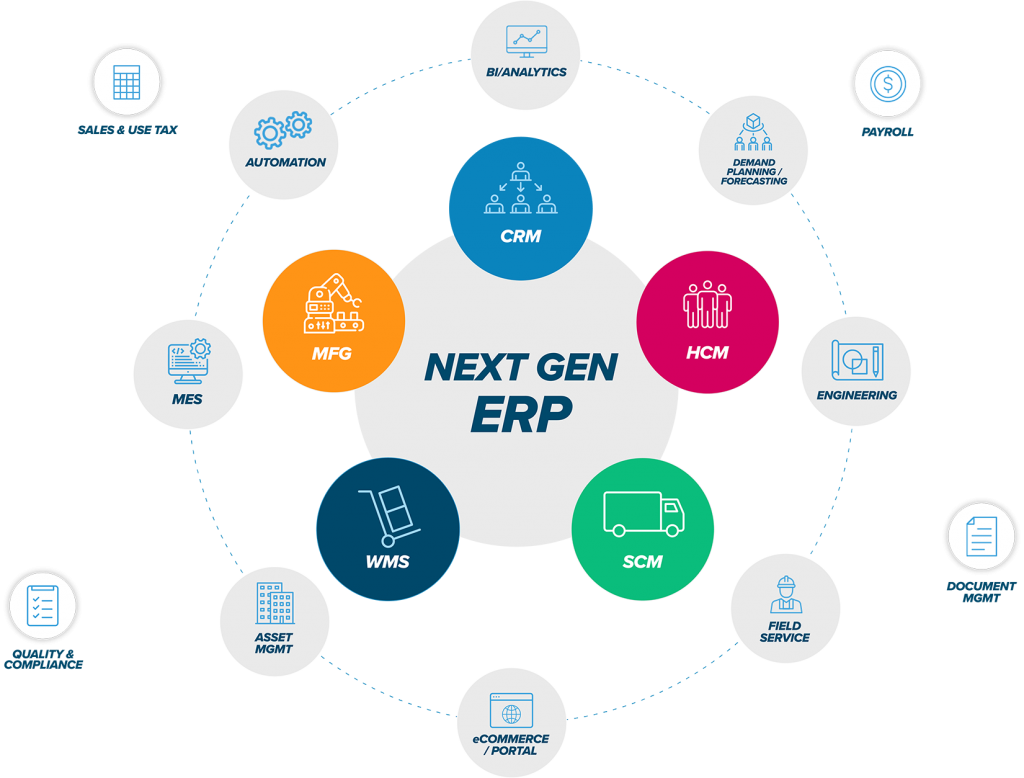

Net at Work also recommended Power Curbers transition from SalesLogix CRM to Microsoft Dynamics 365 Sales and Customer Service, integrated with Sage X3, to bring new visibility and efficiency throughout the organization. Combined, these Next Generation ERP solutions form the core of the industrial manufacturer’s Digital Operations Platform (DOP) that extends the ERP ecosystem to include customers, suppliers, employees and other stakeholders.

“I’d recommend Net at Work to other manufacturers with complex operations because of the breadth and depth of their expertise. It would be very difficult to find another partner like Net at Work” – Mark Hofer, CFO of Power Curbers

CURBING WASTE

As a result of their investment in their Net at Work relationship and Next Generation applications, Hofer says, “We were successfully invoicing within a week of going live with Sage X3.” Power Curbers credits the platform and Net at Work’s consulting team with enabling Power Curbers to further hone its lean manufacturing techniques and Kanban methodologies, allowing it to respond more quickly to the supply chain challenges facing so many companies.

“We successfully relied on just-in-time for years, but that doesn’t work anymore,” explains Crystal Tollenaer, Parts and Production Control Manager for Power Curbers. “Now we need to know where parts are in the system, if there are substitute parts or alternate suppliers, and what our order backlog looks like. Net at Work has helped us configure Sage X3 to give us those answers so we can remain agile and productive.”

By eliminating disconnected processes and bottlenecks, the company can focus on optimizing its manufacturing processes, improving quality and efficiency at every step.

Armed with its DOP foundation, Power Curbers has been able to effectively double in size, gaining newfound efficiencies and insights into operations. The results include shaving 25 minutes from the order entry process using the Sage X3 Configurator, and gaining new visibility into inventory levels which allows it to lower holding costs while meeting demand.

“I’d recommend Net at Work to other manufacturers with complex operations because of the breadth and depth of their expertise. It would be very difficult to find another partner like Net at Work,” says Hofer.

Download the full Net at Work success story to learn more about Power Curber Companies’ approach to implementing an industrial manufacturing DOP solution.